Add to Cart

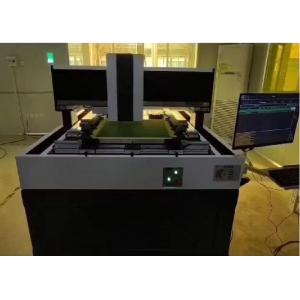

Computer to screen (CTS) / Pre-Press No Film Exposure Screen Laser Direct Plate Making Machine Textile

CTS Process

Compatible Processes with the Conventional Process.Data files can be directly read by the CTS and convented to images. The images will preform exposure imaging on screen by laser heads projection.

Advantages

The maximum screen frame size can reach 900x1000.

|

Specification / Model |

CTS100 |

| Max screen size ( mm ) | 900x1000 |

| Min screen size ( mm ) | 400x400 |

|

Max exposure size ( mm ) |

800x900 |

| Screen frame thickness (bespoke service is available) |

25-45mm |

| Imaging System | DMD DLP Technology |

| Emulsion thickness (EOM) | Solvent resistant emulsion 3μm-150μm, water resistant emulsion 3μm- 220μm |

| Exposure time | 120-240s/ ㎡, #350 yellow mesh |

| Resolution | 1270 |

| Raster | 133LPI |

| Focus system | Fixed focusing |

| File format | 1_bit tiff etc. |

| Laser type | UV laser, wavelength 405±5nm |

| Laser power | 20W |

| Equipment size (mm) | 1550x1330x1460 |

| Equipment net weight | 1100KG |

| Conditions | Yellow light room with cleanliness Class 10000, temperature 22±2°C, 40-70% relative humidity (No condensation) |

| Power | Single phase 220v, 50/60HZ, 4KW, Compressed air: 0.6mpa |

High Precision:

Resolutions 1270dpi or 2540dpi, with raster 133lpi/dpi (halftones printing)

High Efficiency:

3 minutes to finish the exposure on screen size 1000mm*1000mm. Stencil making efficieny has been greatly improved due to a lot of time is saved by the accurate exposure alignment and lobor reduction.

Low Cost:

Elimination of film positives. Litho film are becoming increasingly expensive and the number of suppliers on the maket is rapidly decreasing. 1 procedure of CTS digital screen making to replace 5 procedures of from the conventional process